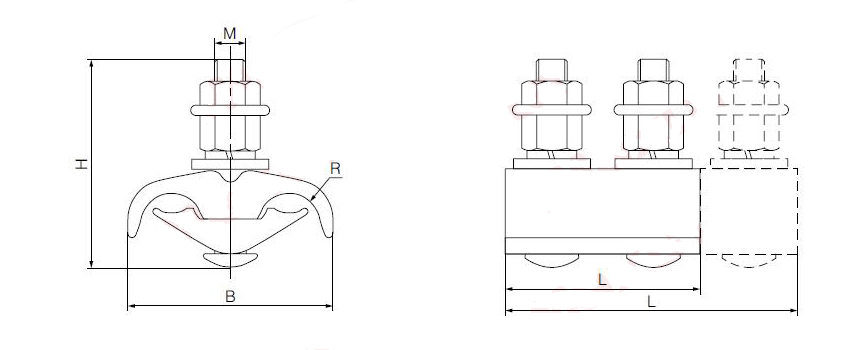

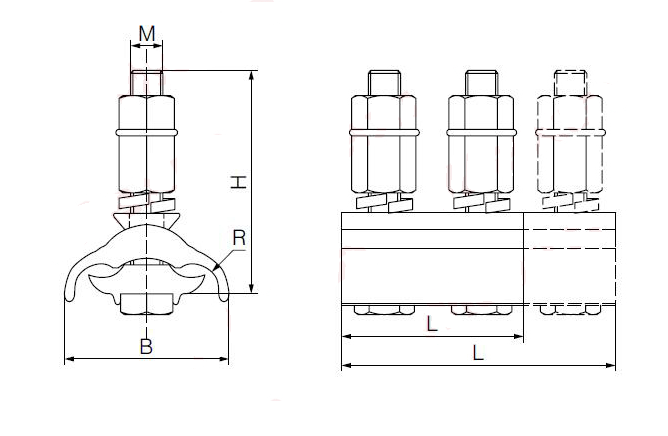

Parallel Groove Clamp

Overview:

Energy-saving torque clamp is the non-load-bearing connection fittings,mainly used in transmission lines, distribution lines and substation line system, splicing and play a lead role in jumpers.

Applicable to aluminium wire,copper wire,overhead insulated wire, ACSR wire,etc., but also for copper wire pair copper wire, aluminum wire to aluminum wire, copper wire to aluminum conductors such transition.

Feature:

1.No limit to voltage grade, capable of reusing.

2.With highly corrosion resistance aluminum alloy, the clamp and the bolt has the good mental elasticity, which forming the energy reserve system with the connecting conductor . Greatly improved the overload capacity and the service life of the clamp.

3.The span design of the clamp can do with different kind of branch line and main line connecting.

4.Special torque nuts can keep constant contact pressure between wire and clamp for a long time and ensure the best installation and good electrical connection of each clip.

5.Trunking clamp the wire in each contact are coated with a conductive unique antioxidants,increased a conductor contact surface ,and effectively block the air and the water, to prevent the contact wire and clamp surface due to oxidation or other corrosion caused less contact.

6.Convenient construction, can be installed perfectly without the special tool, never influence by human factor.,

JBY Instructions for ordering and the technical parameters

PGA Instructions for ordering and the technical parameters

Installation Guide

1. Unpack and check if the product model is matching with the conductor wire, to install it after making sure it’s all correct.

2. Clean up the oil stain and Oxidation Film on the surface of the conductor, until the surface gloss to paint the conductive pipe. (Peel off the conductor if it has the insulation)

3. Loosen the torque nut till the conduct wire can be insert to the sides of the clamp

4. Insert the wire in parallel to the clamp slot