Ingxowa yoomatshini Shear Bolt Lug

Isishwankathelo

Iitheminali zeTorque zenzelwe ngokukodwa ukujongana noqhagamshelo phakathi kweengcingo kunye nezixhobo.

Indlela eyodwa yokucheba ibholithi inika indawo yokumisa engaguqukiyo nethembekileyo.Xa kuthelekiswa namagwegwe esiqhelo e-crimping, ikhawuleza kakhulu kwaye isebenza kakuhle kakhulu, kwaye iqinisekisa umzuzu wokucheba omiselweyo kunye namandla ocinezelo.

Itheminali ye-torsion yenziwe nge-tin-plated aluminium alloy kwaye inodonga olungaphakathi olumile okwegroove.

Into ephawulekayo kukuba inokusindisa abasebenzi kunye nokuphucula ukusebenza kombane kunye noomatshini.

▪ Izinto eziphathekayo: ingxubevange yealuminiyam enkonkxiweyo

▪ Ubushushu bokusebenza: -55℃ ukuya ku-155℃ -67 ℉ ukuya ku-311 ℉

▪ Umgangatho: GB/T 2314 IEC 61238-1

Iimpawu kunye neenzuzo

▪ Uluhlu olubanzi lwezicelo

▪ Uyilo olubambeneyo

▪ Inokusetyenziswa phantse kuzo zonke iindidi zeekhondaktha kunye nemathiriyeli

▪ Ukucheba rhoqo i-torque kuqinisekisa ukusebenza kakuhle kombane

▪ Inokufakwa lula nge-wrench yesokhethi eqhelekileyo

▪ Uyilo oluyinjineli yangaphambili yofakelo olugqibeleleyo kwiintambo zamandla ombane aphakathi ukuya kuthi ga kwi-42kV

▪ Isakhono esihle sempembelelo yangoku yangoku kunye neyokuchasana kwexesha elifutshane

Isishwankathelo

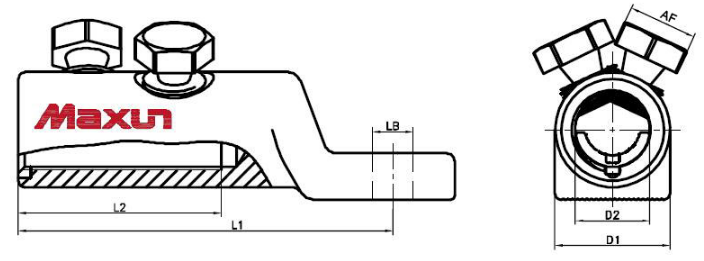

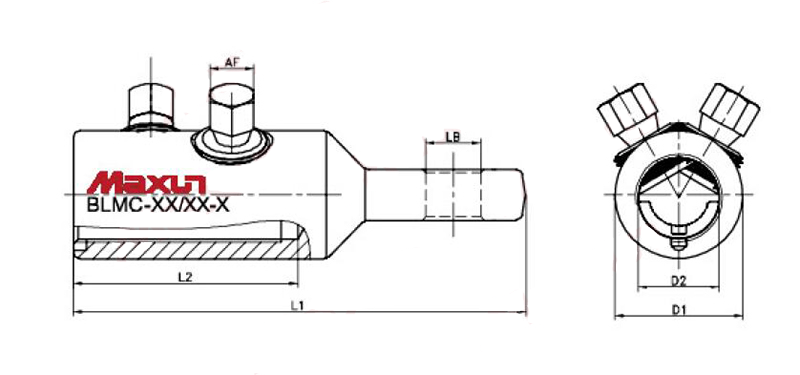

Umzimba we-terminal wenziwe nge-alloy ye-tin-plated ephezulu ye-aluminium.I-terminal ifanelekile kwizicelo zangaphandle kunye nezangaphakathi, kwaye inokubonelela ngemilinganiselo eyahlukeneyo yobukhulu.

| Iimpawu kunye nezibonelelo zeelugs zoomatshini kunye nezihlanganisi | Umsebenzi |

| Uluhlu olubanzi lwesicelo kunye nokuguquguquka okunamandla | Umzekelo, iinkcukacha ezintathu zinokugubungela ama-25mm2 ukuya kuma-400mm2 abaqhubi, |

| Umzimba wenziwe nge-alloy ye-aluminiyam ene-tensile ephezulu | Kwaye inokusetyenziswa phantse kulo lonke uhlobo lomqhubi kunye nezinto eziphathekayo. |

| Iibholiti zenziwe nge-alloy ekhethekileyo ye-aluminium | Iimpawu zoqhagamshelwano ezilungileyo, zinokuqonda unxibelelwano phakathi komqhubi wobhedu kunye nomqhubi we-aluminium. |

| Uyilo oluqinileyo | Kufuneka kuphela indawo encinci yokufakela, ngokukodwa ifanelekile kwizicelo ezinkulu. |

| Uyilo lweTubular spiral ngaphakathi komzimba ukuphucula ukusebenza koqhagamshelwano | Ukusebenza kombane okugqwesileyo. |

| Umngxuma ophakathi kunye nokufaka | Umaleko we-conductor oxide uyahlukana. |

| I-torque rhoqo icheba intloko nati | Isiqwenga seplagi silungelelanisa ubungakanani obunye boqhagamshelo okanye i-terminal efanelekileyo kwiintlobo ezininzi zeengcingo. |

| I-nut ethanjiswayo | Ukufakwa kunceda umqhubi ukuba agxininise ngakumbi kwaye akayi kuphazamisa umqhubi xa i-bolt iqinisiwe. |

| Iimpawu ezikhethekileyo zeetheminali zoomatshini | |

| Umqheba omde | Ngobude obude obongezelelweyo, bunokusetyenziswa njengesithintelo sokufuma |

| Ukutywinwa okuthe tye kufanelekileyo | Ifanelekile kwizicelo zangaphakathi nangaphandle |

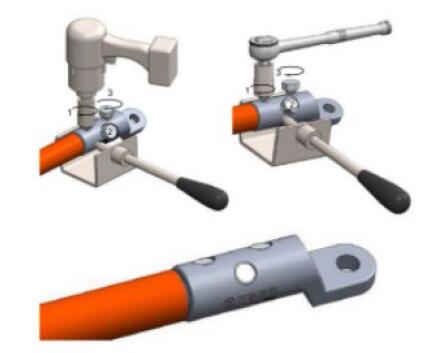

ukufakela

▪ Akukho zixhobo zikhethekileyo ezifunekayo xa kufakelwa, kufuneka kufakwe i-socket wrench kuphela;

▪ Uhlobo ngalunye lusebenzisa ubude obuncitshisiweyo obufanayo, kubandakanywa nokubonelela ngezinto ezifakelweyo;

▪ Uyilo lwentongomane ye-torque ye-torque esisigxina ukuqinisekisa uqhagamshelwano oluthembekileyo noluqinileyo;

▪ Isiqhagamshelo ngasinye okanye ilugi yentambo inomyalelo wokufakela owahlukileyo;

▪ Sincoma ukusebenzisa isixhobo sokuxhasa (jonga isincamatheliso) ukuthintela umqhubi ukugoba.

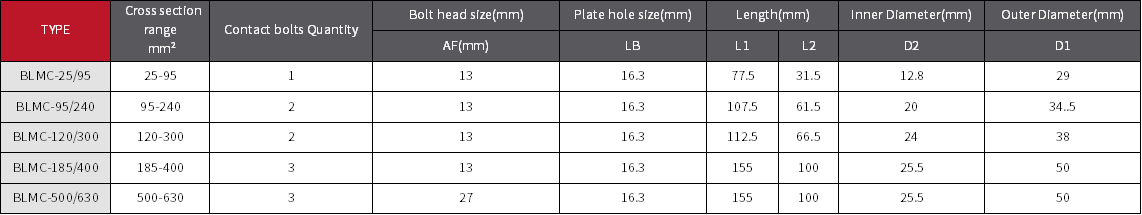

Itheyibhile yokhetho

| Imodeli yemveliso | Umnqamlezo wocingo mm² | Ubungakanani (mm) | Ukunyuka kwemingxuma ububanzi | Ibholithi yoqhagamshelwano Ubungakanani | Iimpawu zeBolt zentloko AF(mm) | Ubude bokukrazula (Mmm) | |||

| L1 | L2 | D1 | D2 | ||||||

| I-BLMT-25/95-13 | 25-95 | 60 | 30 | 24 | 12.8 | 13 | 1 | 13 | 34 |

| I-BLMT-25/95-17 | 25-95 | 60 | 30 | 24 | 12.8 | 17 | 1 | 13 | 34 |

| I-BLMT-35/150-13 | 35-150 | 86 | 36 | 28 | 15.8 | 13 | 1 | 17 | 41 |

| I-BLMT-35/150-17 | 35-150 | 86 | 36 | 28 | 15.8 | 17 | 1 | 17 | 41 |

| I-BLMT-95/240-13 | 95-240 | 112 | 60 | 33 | 20 | 13 | 2 | 19 | 70 |

| I-BLMT-95/240-17 | 95-240 | 112 | 60 | 33 | 20 | 17 | 2 | 19 | 70 |

| I-BLMT-95/240-21 | 95-240 | 112 | 60 | 33 | 20 | 21 | 2 | 19 | 70 |

| I-BLMT-120/300-13 | 120-300 | 120 | 65 | 37 | 24 | 13 | 2 | 22 | 70 |

| I-BLMT-120/300-17 | 120-300 | 120 | 65 | 37 | 24 | 17 | 2 | 22 | 70 |

| I-BLMT-185/400-13 | 185-400 | 137 | 80 | 42 | 25.5 | 13 | 3 | 22 | 90 |

| I-BLMT-185/400-17 | 185-400 | 137 | 80 | 42 | 25.5 | 17 | 3 | 22 | 90 |

| I-BLMT-185/400-21 | 185-400 | 137 | 80 | 42 | 25.5 | 21 | 3 | 22 | 90 |

| I-BLMT-500/630-13 | 500-630 | 150 | 95 | 50 | 33 | 13 | 3 | 27 | 100 |

| I-BLMT-500/630-17 | 500-630 | 150 | 95 | 50 | 33 | 17 | 3 | 27 | 100 |

| I-BLMT-500/630-21 | 500-630 | 150 | 95 | 50 | 33 | 21 | 3 | 27 | 100 |

| I-BLMT-800-13(yenziwe ngokwezifiso) | 630-800 | 180 | 105 | 61 | 40.5 | 13 | 4 | 19 | 118 |

| I-BLMT-800-17(yenziwe ngokwezifiso) | 630-800 | 180 | 105 | 61 | 40.5 | 17 | 4 | 19 | 118 |

| I-BLMT-800/1000-17 | 800-1000 | 153 | 86 | 60 | 40.5 | 17 | 4 | 13 | 94 |

| BLMT-1500-17 (yenziwe ngokwezifiso) | 1500 | 200 | 120 | 65 | 46 | 17 | 4 | 19 | 130 |

Itheminali yeTorque

Izixhobo zokuhlohla ozifunayo:

▪ Isiseko sehexagon kubungakanani obuchanekileyo be-A/F

▪ isitshixo se-ratchet okanye isitshixo sempembelelo yombane

okanye isitshixo sempembelelo yombane

▪ kucetyiswa kakhulu ukusebenzisa isitshixo sokuxhasa ibholithi yokusika xa kukho ukugoba komqhubi

Isikhokelo soFakelo

2. I-conductor yokuphelisa ukufana.ubude be-peel bomqhubi omele unqunywe ngokubhekiselele kwisikhokelo esicetyiswayo.

kuphephe ukusika umqhubi.

3.Ukufaka i-conductor ezantsi kwetheminali ye-torque ngononophelo.

4.qinisa ibholithi yokucheba, ulungise umqhubi kwi-terminal.qinisa ibholithi ukusuka ku-1-2-3